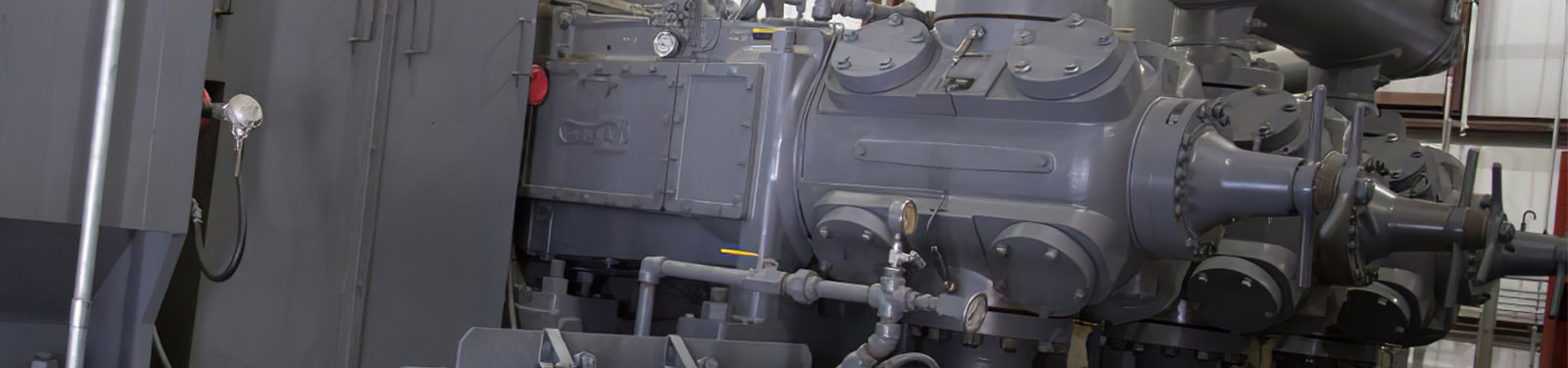

Air compressors must operate reliably for long periods of time without interruption.

The cryogenic processes of cooling and liquefaction in air separation units (ASUs) requires very tight integration of the heat exchangers and separation columns to achieve desirable efficiencies. The ASU separates atmospheric air into its primary components by utilizing a refrigeration cycle that operates based on the Joules-Thomson effect to achieve the ultra-low distillation temperatures required.

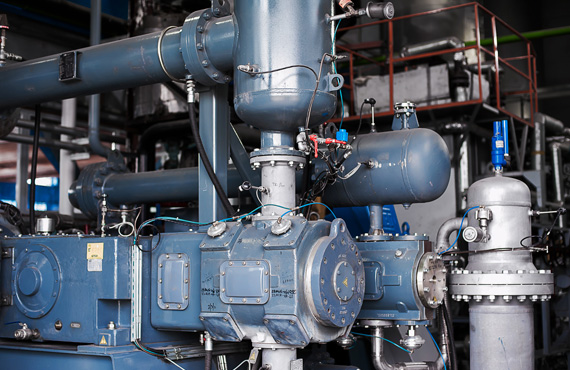

The cooling of the gases is done by air compressors, which require a large amount of energy to make the refrigeration cycle work. The energy for the refrigeration cycle is provided by the compression of air at the inlet of the ASU. The cold equipment including heat exchangers, distillation columns and associated valves and piping must be kept within an insulated enclosure called a "cold box".

Modern ASUs use expansion turbines for cooling; the output of the expander helps drive the air compressor, for improved efficiency. When air compressors fail, it can mean significant downtime, significant maintenance costs, unsafe operating conditions, and lost profitability.