Beyond tube leaks, some of the boiler's supporting equipment is susceptible to failure as well.

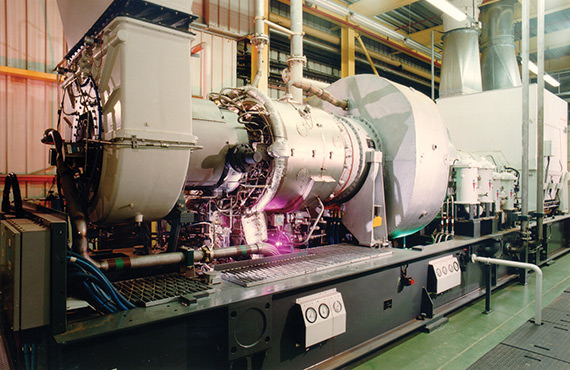

For some rotating assets and the processes associated with them, periodic route-based data collection is insufficient to indicate asset health. Online condition monitoring provides the frequency and types of data necessary to stay on top of developing issues during normal operations and to respond quickly to sudden changes during transient conditions.

For example, rotating equipment such as forced draft (FD), induced draft (ID) and primary air (PA) fans, are critical for ensuring reliable operations. Neglecting maintenance of rotating equipment contributes to forced outages.